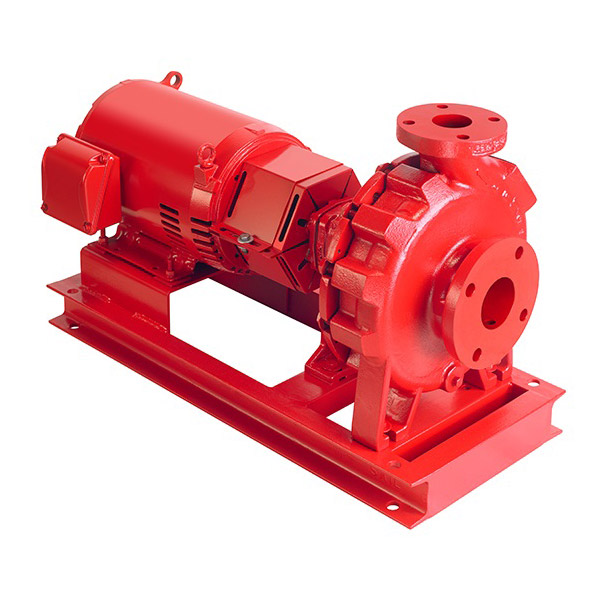

End Suction Pump

- Casing: Cast iron, ductile iron, or bronze

- Impeller: Cast iron or bronze

- Configuration: Inside single spring mechanical seal.

- Performance range: Up to 5,000 USgpm (315 L/s) flow; up to 600 ft (180 m) head

- Temperature: 250°F (121°C)

- Power Range: 0.33 hp to 300 hp (0.25 kW to 200 kW)

- High-efficiency NEMA-premium motors ensure low energy consumption and cost.

- Size:1" to 8” (25 mm to 200 mm)

Low installed cost

- ANSI/HI 1.3.5 rigid free-standing baseplate eliminates grouting

- Pre-lubricated and sealed deep-groove ball bearings for convenient installation (simply pipe, align, wire and start)

Low energy consumption

- Pumps are equipped with high-efficiency NEMA-premium motors for significant reduction in energy consumption and cost.

- All motors are suitable for inverter-fed service

Low operating and maintenance cost

- Pumps are equipped with high-efficiency NEMA-premium motors for significant reduction in energy cost

- ANSI-style centerline discharge casing eliminates air binding

- Sintered silicon carbide mechanical seal seat for longer life

- Confined casing gasket eliminates blow-outs

- Universal replacement seals, bearings, and motors available locally world-wide

Horizontal Split Case Pump

- Casing: Cast-iron, or ductile iron

- Configuration: Inside single spring mechanical seal

- Performance range: Up to 7,000 USgpm (440 L/s) flow; up to 600 ft (180 m) head

- Temperature: 225°F (107°C)

- Power Range: 1.5 hp to 500 hp (1.1 kW to 400 kW)

- High-efficiency NEMA-premium motors ensure low energy consumption and cost.

- Size: 4" to 10" (100 mm to 250 mm)

Low installed cost

- ANSI/HI 1.3.5 rigid free-standing baseplate eliminates grouting

Low energy consumption

- Pumps are equipped with high-efficiency NEMA-premium motors for significant reduction in energy consumption and cost

- Tilted-parting concept to maximize efficiency and reduce inlet turbulence

- All motors are suitable for inverter-fed service

Low maintenance cost

- Leaking seals or noisy bearings can be serviced in minutes without disturbing other components

- No lubrication or seal adjustments required

- Integral bearing nut for easy bearing removal and re-use

- Mechanical seals and bearings can be replaced easily without opening the pump casing

- Unique cartridge design mechanical seal that uses a standard replacement seal

- Universal replacement seals, bearings, and motors available locally world-wide

Vertical Inline Pump

- Casing: Cast, ductile iron or bronze

- Impeller: Cast iron or bronze

- Configuration: Outside balanced or inside single spring mechanical seal

- Performance range: Up to 28,000 USgpm (1,800 L/s) flow; up to 500 ft (150 m) head

- Temperature: 300oF (150oC)

- Power Range: 1 hp to 1250 hp (0.75 kW to 900 kW)

- Size: 1.5" to 20” (40 mm to 500 mm)

Low installed cost

- Vertical In-line design minimizes space and pipe requirements

- Eliminates the need for inertia bases, housekeeping pads, flex connectors, and field alignment or grouting requirements

- Isolated mechanical seal design with optional sediment filters / separators available to extend seal life in contaminated systems

Low energy consumption and operating cost

- Pumps are available with high-efficiency NEMA-premium motors for significant reduction in energy consumption and cost

- All motors are suitable for inverter-fed service

- Vertical In-line design minimizes pipe requirements and related friction losses resulting in higher system efficiency

- Split-coupling allows replacement of mechanical seal without disturbing the pump or motor

- No lubrication or seal adjustments required

Low operating risk

- Universal replacement seals, bearings, and motors available locally world-wide

- Optional isolated mechanical seal with sediment filters or separators for extended seal life in contaminated systems

- Vertical In-Line configuration allows for less disruptive pump service (casing stays in place)

Design Envelope Pump

- Design Envelope offers the lowest installed cost and the lowest life cost of any pumping solution today

- up to 65% installed cost savings

- up to 80% energy savings

- Most systems operate at less than 60% capacity 90% of the time or more.Design Envelope pumps are designed for high efficiency operation at part load

- Design Envelope solutions reduce pumping costs through variable speed, ...demand-based operation

- It also ensures that the installation meets or exceeds ashrae 90.1 guidelines ...requiring 70% energy savings at 50% of peak load.

- Equipped with Sensorless technology, Design Envelope solutions do not require ...an external sensor to monitor and control the hvac load.