Axial Fans

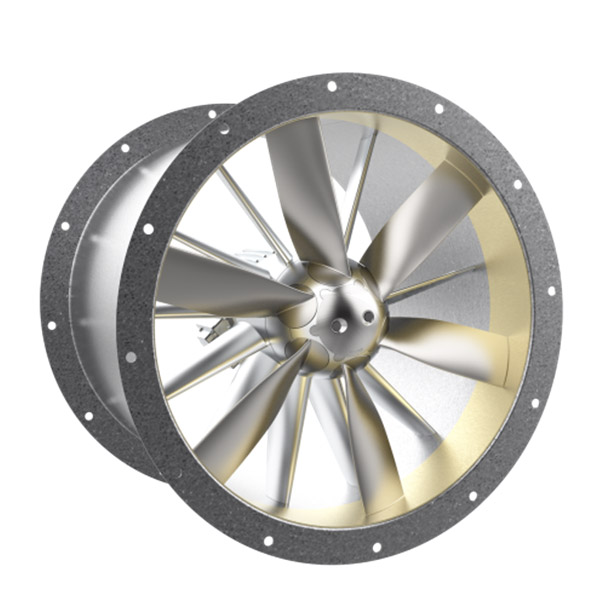

Axial Flow Fans ZerAx AZL

- The ZerAx AZL are unidirectional axial flow fans

- For installation in AHUs and retrofitting

- 13 sizes with impeller diameters from Ø250 to Ø1000 mm

- Two hub sizes – Ø160 or Ø350 mm

- Fan casing thicknesses of 2 or 3 mm

- Airflow rates : 0.1 to 33 m3/s (350 to 119.000 m3/h)

- Pressures up to 3300 Pa

- Efficiencies up to 92%

- Adjustable blade angles

- Impeller, guide vanes and motor mount of aluminium

Axial Flow Fans ZerAx AZN

- The ZerAx AZN are unidirectional axial flow fans

- For duct installation

- 19 sizes with impeller diameters from Ø250 to Ø2000 mm

- Three hub sizes – Ø160, Ø350 or Ø560 mm

- Fan casing thicknesses of 2 or 4 mm

- Airflow rates: 0.1 to 110 m3/s (350 to 396,000 m3/h)

- Pressures up to 3400 Pa

- Efficiencies up to 92%

- Adjustable blade angles

- Impeller, guide vanes and motor mount of aluminium

Axial Flow Fans ZerAx AZL AZN Standard Ranges

- For temperatures between -20 and +50 °C

- For duct (AZL and AZN) and bracket (AZL) installation

- 187 (AZL) and 24 (AZN) predefined combinations of fan and hub sizes, airflows and pressures

- Impeller diameters

- AZL: Ø250 to Ø1000 mm

- AZN: Ø250 to Ø900 mm

- Airflow rates (optimum)

- AZL: 0.75 to 19.6 m3/s -> 2,700 to 70,500 m3/h

- AZN: 0.83 to 11.9 m3/s -> 3,000 to 42,800 m3/h

- Total pressures (optimum)

- AZL: up to 2400 Pa

- AZN: up to 1400 Pa

- Fan efficiencies at optimum up to 91%

- Air-over motors (cooling)

- Impeller blades and hubs of aluminium

Axial Flow Fans NovAx ACN Standard Range

- The NovAx ACN Standard Range fans for standard temperatures are unidirectional fans for conventional and industrial use.

- For duct installation

- 30 predefined combinations of fan and hub sizes, airflows and pressures

- Impeller diameters for ACN Standard Range fans from Ø400 to Ø1400 mm

- Airflow rates: 1.4 to 27.8 m3/s

- Total pressures up to 1300 Pa

- Efficiencies up to 83%

- Air-over motor (cooling)

- Fan casings and hubs of galvanised steel

- Impeller blades of aluminium

Axial Flow Fans NovAx ACP ACG

- The NovAx ACP and ACG are unidirectional axial flow fans for conventional, industrial and marine use.

- Mounting

- ACP: For wall or bulkhead

- ACG: For duct connection

- Fan sizes

- 14 sizes from Ø250 to Ø1600 mm

- Seven hub sizes from Ø160 to Ø578 mm

- Fan casing thicknesses of 2.5, 3 or 4 mm depending on size

- Airflow rates: 0.1 to 65 m3/s

- Pressures up to 2000 Pa

- Efficiencies up to 83%

- Adjustable blade angles

- Integrated inlet cone

Axial Flow Fans NovAx ARN

- The NovAx ARN are fully reversible axial flow fans for conventional and industrial use.

- For duct installation

- Six sizes with impeller diameters from Ø900 to Ø1600 mm

- Two hub sizes, Ø403 or Ø578 mm

- Fan casing thicknesses of 2 or 4 mm

- Airflow rates: 5 to 50 m3/s

- Pressures up to 1200 Pa

- Efficiencies up to 75%

- 100% reversible

- Adjustable blade angles

- Air over motor (cooling)

- Fan casing and hub of galvanised steel

- Impeller blades of aluminium; guide vanes and motor mount of galvanised steel

Smoke Fans

Smoke Fans ZerAx® HT AZL

- Smoke exhaust fans are for conventional ventilation and for operation during fires

- Free inlet (integrated inlet cone)

- Outlet duct installation

- 13 sizes with impeller diameters from Ø250 to Ø1000 mm

- Two hub sizes – Ø160 or Ø350 mm

- Fan casing thicknesses of 2 or 3 mm

- Airflow rates: 0.1 to 33 m3/s (350 to 119,000 m3/h)

- Pressures up to 3100 Pa

- Efficiencies up to 89%

- Adjustable blade angles

- F300 certified according EN 12101 part 3 in combination with variable speed drive (VSD)

- Air over motor (cooling)

- Impeller, guide vanes and motor mount of aluminium

Smoke Fans ZerAx® HT AZN

- Smoke exhaust fans are for conventional ventilation and for operation during fires

- For duct installation

- 19 sizes with impeller diameters from Ø250 to Ø2000 mm

- Three hub sizes – Ø160, Ø350 or Ø560 mm

- Fan casing thicknesses of 2 or 4 mm

- Airflow rates: 0.1 to 110 m3/s (350 to 396,000 m3/h)

- Pressures up to 3100 Pa

- Efficiencies up to 89%

- Adjustable blade angles

- F300 certified according EN 12101 part 3 in combination with variable speed drive (VSD)

- Air over motor (cooling)

- Impeller, guide vanes and motor mount of aluminium

Smoke Fans NovAx ACN

- Smoke exhaust fans are for conventional operation and operation during fires

- For duct installation

- 12 sizes with impeller diameters from Ø400 to Ø1600 mm

- Six hub sizes from Ø230 to Ø578 mm

- Fan casing thicknesses of 2 or 4 mm

- Airflow rates from 0.2 to 65 m3/s

- Pressures up to 1800 Pa

- Efficiencies up to 83%

- Adjustable blade angles

- F200, F300 and F400 certified according EN 12101 part 3

- Air over motor (cooling)

- Fan casing and hub of galvanised steel

- Impeller blades of aluminium

Smoke Fans NovAx ACN Standard

- Smoke exhaust fans are for conventional operation and operation during fires

- For duct installation

- 26 predefined combinations of fan and hub sizes, airflows and pressures

- Impeller diameters from Ø500 to Ø1400 mm

- Airflow rates from 2.8 to 27.8 m3/s

- Total pressures up to 1300 Pa

- Efficiencies up to 83%

- F300 certified according EN 12101 part 3

- Air over motor (cooling)

- Fan casing and hub of galvanised steel

- Impeller blades of aluminium

Smoke Fans NovAx ACP ACG

- Smoke exhaust fans are for conventional, industrial and marine environments and suitable for operation during fires

- Mounting

- ACP: For wall or bulkhead

- ACG: For duct ends

- 12 sizes from Ø400 to Ø1600 mm

- Seven hub sizes from Ø160 to Ø578 mm

- Fan casing thicknesses of 2.5, 3 or 4 mm depending on size

- Airflow rates from 0.2 to 65 m3/s

- Pressures up to 2000 Pa

- Efficiencies up to 83%

- Adjustable blade angles

- F200, F300 and F400 approved for smoke extract

- Integrated inlet cone

- ACG: Additional guide vane arrangement

Smoke Fans NovAx ARN

- Smoke exhaust fans are fully reversible and for conventional operation and operation during fires

- For duct installation

- Six sizes with impeller diameters from Ø900 to Ø1600 mm

- Two hub sizes, Ø403 or Ø578 mm

- Fan casing thicknesses of 2 or 4 mm

- Airflow rates: 5 to 50 m3/s (18,000 to 180,000 m3/h)

- Pressures up to 1200 Pa

- Efficiencies up to 75%

- 100% reversible

- Adjustable blade angles

- Air over motor (cooling)

- F200, F300 and F400 certified according EN 12101 part 3

- Fan casing and hub of galvanised steel

- Impeller blades of aluminium; guide vanes, hubs and motor mount of galvanised steel

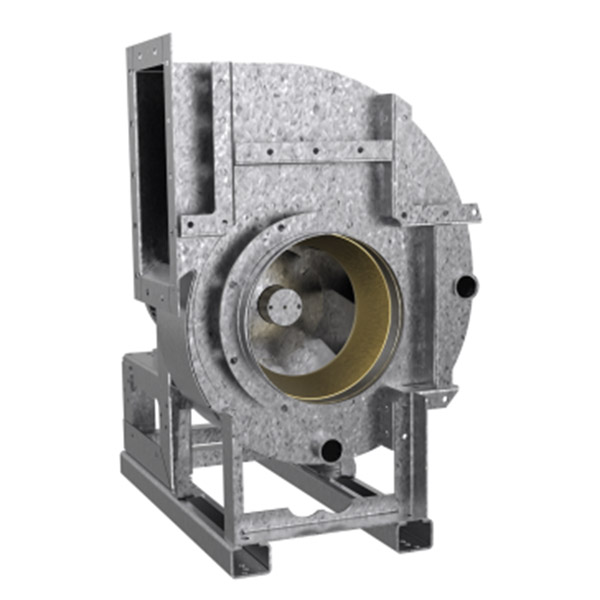

Centrifugal Fans

Centrifugal Fans CAL

- Robust centrifugal flow fan for operation in aggressive environments

- For flange connection

- 9 sizes with impeller diameters from Ø400 to Ø1250 mm

- Airflow rates

- 0.3 to 21 m3/s

- 1100 to 75600 m3/h

- Pressures

- Up to 8500 Pa

- Direct coupled motor

- Backward-curved blades

- Housing, impeller, brackets and guide vanes of steel

Centrifugal Fans CNA CNB

- Low-pressure centrifugal flow fans for operation in non-corrosive environments

- For flange connection

- Impeller diameters

- CNA: 9 sizes from Ø250 to Ø1000 mm

- CNB: 7 sizes from Ø400 to Ø1000 mm

- Airflow rates

- CNA: 0.2 to 14 m3/s (720 to 50400 m3/h)

- CNB: 0.8 to 18 m3/s (2880 to 64800 m3/h)

- Pressures

- CNA: Up to 1000 Pa

- CNB: Up to 1500 Pa

- Direct coupled or belt-driven versions

- Backward-curved blades

- Housing and impeller of hot-dip galvanised sheet steel

Centrifugal Fans CNA Standard Range

- Low-pressure centrifugal flow fans for operation in non-corrosive environments at standard temperatures

- 10 fixed size-motor combinations

- For flange connection

- Impeller diameters

- Ø250, Ø315 and Ø400 mm

- Optimum airflow rates

- 0.4 to 0.8 m3/s (1440 to 2880 m3/h)

- Total pressures

- 483 to 1000 Pa

- Direct coupled

- Backward-curved blades

- Housing and impeller of hot-dip galvanised sheet steel

Centrifugal Fans CND CNF

- Low and medium pressure centrifugal flow fans for operation in corrosive environments

- For flange connection

- Impeller diameters

- 7 sizes from Ø315 to Ø710 mm

- Airflow rates

- CND: 0.2 to 10 m3/s (720 to 36000 m3/h)

- CNF: 0.2 to 11 m3/s (720 to 39600 m3/h)

- Pressures

- CND: Up to 2000 Pa

- CNF: Up to 4000 Pa

- Direct coupled or belt-driven versions

- Backward-curved blades

- Housing and impeller of hot-dip galvanised sheet steel

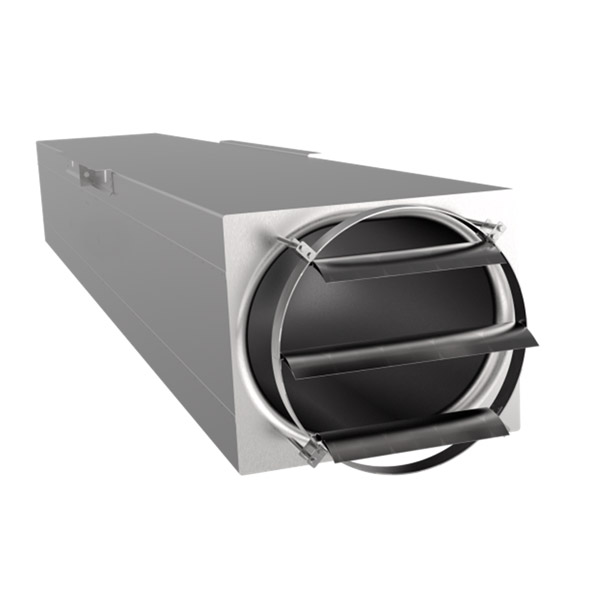

Car Park Jet Fans

Jet Fans AUZ ARP

- Oval design car park jet fans in a unidirectional (AUZ) and fully reversible (ARP) version.

- This range of oval jet fans excels in low noise levels.

- The installation height is 422mm.

- The internal fan housing consists of a round fan casing with flanges.

- Oval silencers have been mounted on both sides on the fan casing.

- With deflectors the air stream flows in the desired direction.

- On the reversible version deflectors are mounted on both sides of the fan.

- The impeller is coupled directly onto the motor shaft.

- The silencers are an Aluzink execution.

- A powder coating in any desired color is available as an option.

- As standard, the fan casings and mounting frames are hot-dip galvanized steel.

- The fan has been constructed with guide vanes for an optimal aerodynamic efficiency.

- On the unidirectional version a wire guard is mounted on the inlet side and a deflector on the discharge side.

- As standard, the jet fans are equipped with mounting feet for direct mounting to the ceiling or wall.

- The impeller consists of a hub in which special casted aluminium impeller blades have been mounted

- The impeller is coupled directly onto the motor shaft.

- All fans are statically and dynamically balanced in acc. with VDI 2060, ISO 1940, 1-1986 Class Q 6.3.

- The motor is two-speed 3x400V, 50Hz or 3x380V, 60Hz for direct start.

- Motor protection min. IP55 in accordance with IEC 34-5.

- Insulation class F or H depending on temperature protection.

- The jet fans are equipped with a terminal box on the outside of the fan casing.

- As standard, the fan casings and mounting frames are hot-dip galvanized steel.

- The silencers are an Aluzink execution.

- A powder coating in any desired color is available as an option.

- The standard operating temperature is from -20 until +40°C.

- Jet fans for hot smoke removal are certified according to the EN 12101 part 3 in the classes F200/F300/F400.

- All F300 fans have been tested at 300°C / 120 min

- Class F400 is only available for 50Hz

Jet Fans AUT ART

- Basic car park jet fans in a unidirectional (AUT) and fully reversible (ART) version.

- The installation height is 422 mm.

- On both sides internal wire guards are mounted.

- With a special internal deflector the air stream flows in the desired direction.

- On the reversible version internal deflectors are mounted on both sides of the fan.

- The impeller is coupled directly onto the motor shaft.

- As standard, all jet fans are delivered in a galvanized execution.

- A powder coating in any desired color is available as an option.

- The jet fan consists of a round fan casing with an inlet cone on both sides to minimize the inlet losses.

- The fan has been constructed with guide vanes for an optimal aerodynamic efficiency.

- As standard, the jet fans are equipped with mounting feet for direct mounting to the ceiling or wall.

- The impeller consists of a NovAx hub in which special casted aluminium impeller blades have been mounted at a pre-determined pitch angle.

- All NovAx fans are statically and dynamically balanced in accordance with VDI 2060, ISO 1940 Class Q 6.3.

- The motor is two-speed 3x400V, 50Hz or 3x380V, 60Hz for direct start.

- Motor protection min. IP55 in accordance with IEC 34-5.

- Insulation class F or H depending on temperature protection.

- The jet fans have external terminal boxes.

- As standard, all jet fans are delivered in a galvanized execution.

- A powder coating in any desired color is available as an option.

- The standard operating temperature is from -20 to +40°C.

- Jet fans for hot smoke removal are certified according to the EN 12101 part 3 in the classes F200/F300/F400.

- All F300 fans have been tested at 300°C / 120 min

- Class F400 is only available for 50Hz

Jet Fans AUO ARO

- The ARO-AUO are reversible (ARO) and unidirectional (AUO) jet fans for conventional operation and operation during fires in car parks.

- Three impeller diameters of Ø290, Ø380 or Ø500 mm

- Standard temperature range -20 to +40°C

- Thrusts between 5 and 111 N

- Sound pressures between 35 and 64 dB(A)

- Two-speed motors are standard

- Low sound level

- F200, F300 and F400 approved for smoke extract

- Outer casing of 3 mm sheet steel

- Hub of galvanised steel

- Impeller blades of aluminium

- Deflectors on the outlets and for ARO also on the inlet

- Wire guard on the inlet for AUO

Jet Fans AZT

- Compact and unidirectional car park jet fans (AZT) with adjustable outlet and low fan height.

- The fan casing is round with an integrated inlet cone and an adjustable outlet cone.

- The fan has guide vanes to improve the aerodynamic efficiency.

- A wire guard is mounted on the inlet cone.

- The motors are two-speed 3x400V or 3x380V, both in 50 or 60Hz versions.

- Motor protection is min. IP55 in accordance with IEC 34-5.

- The jet fans have external terminal boxes.

- The impeller consists of a ZerAx hub with aluminium impeller blades in pre-determined pitch angles.

- All ZerAx fans are statically and dynamically balanced in accordance with VDI 2060, ISO 1940 Class Q 6.3.

- The fan casing is of pre-galvanised sheet steel, which can be optionally powder coated in any desired colour.

- The standard operating temperature is from -20 to +55°C.

- The fans for are certified for removal of hot smoke according to the EN 12101 part 3 in the classes F200120 and F30060.

- F200120 fans tested at 300°C / 120 min

- F30060 fans tested at 300°C / 120 min

Jet Fans CGF

- Centrifugal design car park jet fans in a unidirectional execution.

- The jet fan consists of a flat centrifugal fan Aluzink casing with an inlet cone on the bottom side to minimize the inlet losses.

- On the inlet side wire guards are mounted.

- With a special internal deflector the air stream flows in the desired direction.

- As standard, the jet fans are equipped with mounting feet for direct mounting to the ceiling.

- All fans are statically and dynamically balanced in accordance with VDI 2060, ISO 1940 Class Q 6.3.

- The motor is two-speed 3x400V, 50Hz for direct start.

- Motor protection min. IP55 in accordance with IEC 34-5.

- Insulation class F or H depending on temperature protection.

- The centrifugal jet fans have a terminal box which is integrated into the fan housing.

- As standard, all jet fans are delivered in an Aluzink execution.

- The standard operating temperature is from -20°C until +40°C.

- Jet fans for hot smoke removal are certified in accordance to the EN 12101-3 in the classes F200 and F300.

- All F300 fans have been tested at 300°C / 120 min

Tunnel Ventilation

Jet Fans ARC AUC

- The ARC-AUC are height-saving reversible (ARC) and unidirectional (AUC) tunnel fans

- The design is characterised by a space-saving rectangular design

- Compared to standard round tunnel fans, the installation height is approximately 20% less.

- Three impeller diameters of Ø630, Ø710 or Ø800 mm

- Standard temperature range -20 to +40 °C

- Thrusts

- AUC: Up to 816 N

- ARC: Up to 712 N

- Sound power

- No core: between 89 and 99 dB(A)

- With core: between 87 and 98 dB(A)

- Sound pressure at 10 m/45° free field conditions

- No core: between 61 and 71 dB(A)

- With core: between 59 and 70 dB(A)

- F200, F300 and F400 approved for smoke extract

- Material static parts

- Hot-dip galvanised sheet steel or

- Stainless steel

- Hub of galvanised steel

- Optional: Powder coated

- Impeller blades of aluminium

- Deflectors on the outlets and for ARC also on the inlet

- Wire guard on the inlet for AUC

Jet Fans ARR AUR

- The ARR-AUR are reversible (ARR) and unidirectional (AUR) tunnel fans

- The design is characterised by the circular silencers and employs the renowned NovAx axial flow fans.

- Nine impeller diameters of Ø630 to Ø1600 mm

- Standard temperature range -20 to +40 °C

- Thrusts

- AUR: Up to 2882 N

- ARR: Up to 2755 N

- Sound power

- 1D silencers: between 98 and 113 dB(A)

- 2D silencers: between 94 and 109 dB(A)

- Sound pressure at 10 m/45° free field conditions

- 1D silencers: between 70 and 85 dB(A)

- 2D silencers: between 66 and 81 dB(A)

- F200, F300 and F400 approved for smoke extract

- Material static parts

- Hot-dip galvanised sheet steel or

- Stainless steel

- Hub of galvanised steel

- Optional: Powder coated

- Impeller blades of aluminium

- Deflectors on the outlets and for ARR also on the inlet

- Wire guard on the inlet for AUR

ATEX & EX Fans

Axial Flow Fans ZerAx AZN ATEX and AZN AZW EX

- The Novenco ZerAx AZN ATEX are unidirectional axial flow fans that comply with the EU's ATEX directive 2014/34/EU for equipment in explosive atmospheres and environments

- The field of application is for removal of air in connection with transport of polluted air, hazardous gases and dust.

- The products are also in accordance to the international guidelines for non-sparking fans in marine environments.

- For duct installation

- Impeller diameters

- AZN: 13 sizes from Ø250 to Ø1250 mm

- AZW: 9 sizes from Ø500 to Ø1250 mm

- Hub sizes

- AZN: Ø160 or Ø350 mm

- AZW: Ø350 mm

- Fan casing thicknesses

- AZN: 2 or 4 mm

- AZW: 10 mm

- Airflow rates from 0.1 to 42 m3/s

- Pressures up to 3300 Pa

- Efficiencies up to 92%

- Adjustable blade angles

- Impeller, guide vanes and motor mount of aluminium

- Classifications

- ATEX: Category 2G/D according to EU directive 2014/34/EU

- EX: Non-sparking fans according to guideline IACS F29/2005

Axial Flow Fans NovAx ACN-ACW ATEX and ACW EX

- The NovAx ACN-ACW ATEX and ACW EX are unidirectional axial flow fans that comply with the ATEX directive 2014/34/EU for equipment in explosive atmospheres and environments.

- The field of application is for removal of air in connection with transport of polluted air, hazardous gases and dust.

- For duct installation

- Impeller diameters

- 14 sizes from Ø250 to Ø1600 mm

- Hub sizes

- 7 sizes from Ø160 to Ø578 mm

- Fan casing thicknesses

- ACN: 2, 3 or 4 mm

- ACW: 6 or 10 mm

- Airflow rates from 0.1 to 65 m3/s

- Pressures up to 2000 Pa

- Efficiencies up to 83%

- Adjustable blade angles

- Fan casing of galvanised steel

- Impeller and hub of aluminium

- Classifications

- ATEX: Category 2G/D according to EU directive 2014/34/EU

- EX: Non-sparking fans according to guideline IACS F29/2005

Centrifugal Fans CAL ATEX and EX

- The CAL are robust centrifugal flow fans that comply with the ATEX directive 2014/34/EU for equipment in explosive atmospheres and environments.

- The field of application is for removal of air in connection with transport of polluted air, hazardous gases and dust.

- For flange connection

- 9 sizes with impeller diameters from Ø400 to Ø1250 mm

- Airflow rates: 0.3 to 21 m3/s (1100 to 75600 m3/h)

- Pressures up to 8500 Pa

- Direct coupled

- Backward-curved blades

- Motor and impeller can be dismounted from the motor side

- Housing, impeller, brackets and guide vanes of steel

- Surface treatment of hot-dip galvanisation

- Classifications

- ATEX: Category 2G/D according to EU directive 2014/34/EU

- EX: Non-sparking fans according to guideline IACS F29/2005

Centrifugal Fans CNA CNB EX

- The CNA-CNB EX are low-pressure centrifugal flow fans for operation in non-corrosive environments.

- The fans are suited for transport of air containing flammable gases.

- The design is for universal installation in light industrial plants.

- For flange connection

- Impeller diameters

- CNA: 9 sizes from Ø250 to Ø1000 mm

- CNB: 7 sizes from Ø400 to Ø1000 mm

- Airflow rates

- CNA: 0.2 to 14 m3/s (720 to 50400 m3/h)

- CNB: 0.8 to 18 m3/s (2880 to 64800 m3/h)

- Pressures

- CNA: Up to 1000 Pa

- CNB: Up to 1500 Pa

- Direct coupled or belt-driven versions

- Backward-curved blades

- Low sound level

- Can be mounted in any position

- Housing and impeller of hot-dip galvanised sheet steel

- Inlet cone of brass

- Classifications

- EX: Non-sparking fans according to guideline IACS F29/2005

- Corrosion category C2 according to DS/EN ISO 12944-2

Centrifugal Fans CND CNF ATEX and EX

- The CND-CNF ATEX and EX are low and medium pressure centrifugal flow fans.

- The ATEX versions comply with directive 2014/34/EU for equipment in explosive atmospheres and environments. The field of application is for removal of air in connection with transport of polluted air, hazardous gases and dust.

- The EX versions meet the guidelines IACS F29/2005 for non-sparking fans. The fans are suited for transport of air containing flammable gases.

- For flange connection

- 7 sizes with impeller diameters from Ø315 to Ø710 mm

- Airflow rates

- CND: 0.2 to 10 m3/s (700 to 36000 m3/h)

- CNF: 0.2 to 11 m3/s (700 to 39600 m3/h)

- Pressures

- CND: Up to 2000 Pa

- CNF: Up to 4000 Pa

- Direct coupled or belt-driven versions

- Backward-curved blades

- Low sound level

- Can be mounted in any position

- Housing and impeller of hot-dip galvanised sheet steel

- EX: Inlet cone of brass

- Classifications

- ATEX: Category 2G/D according to EU directive 2014/34/EU

- EX: Non-sparking fans according to guideline IACS F29/2005

- Corrosion category C5-I (very high) according to DS/EN ISO 12944-2

Circular Inline Ducted Fans

- Duct fan with circular connections.

- Proven performance and reliability.

- Compact with high capacity and efficiency.

- Low sound levels.

- Operational in both 50 and 60 Hz.

- CK is available with AC or EC motor.

- Impeller with backward curved blades.

- The external rotor motor has maintenance-free sealed ball-bearings and is very energy efficient.

- For speed control a transformer or electronic speed controller can be connected.

- Integrated motor protection.

- Junction box has enclosure class IP 54.

- Fan housing is manufactured from galvanized sheet steel.

- The fan is intended to be installed in a duct system.

- A duct connected fan can be installed outside or in damp environments.

- Easy installation in any position.

Cabinet Type Fans

- Duct fan with square / Circular connections.

- High capacity and very good efficiency.

- Operational in both 50 and 60 Hz.

- Impeller with backward curved blades.

- The external rotor motor has maintenance-free sealed ball-bearings.

- Integrated motor protection.

- Available with AC or EC motors

- Junction box has enclosure class IP 54.

- For speed control a transformer or electric speed controller can be connected.

- Fan housing is manufactured from galvanized sheet steel.

- The fan is intended to be installed in a duct system.

- A duct connected fan can be installed outside or in damp environments.

- Easy installation in any position.