Water Cooled Centrifugal Chiller

LG's Centrifugal Chiller with optimized Two-stage compressing cycle, energy efficiency has been improved and operation costs has been reduced.

High Efficiency Two-stage Compressor:

Centrifugal Chiller achieved world’s top COP through High Efficiency Two-stage Compressor. With optimized Two-stage compressing cycle, energy efficiency has been improved and operation costs has been reduced as opposed to the previous One-stage Centrifugal Chiller.

Compact Size & Light Weight:

Two-stage compressing technology with optimized installation enables to create extra capacity by reducing the size and weight in comparison to the previous model.

Stable Operation

Excellent partial load system can save cost and maximize energy even when the loads are very light.

Water Cooled Screw Chiller

LG's Water-cooled Screw Chiller with its Ice Storage System cools the indoor area during the day and produces ice throughout the night. LG will revolutionize the way you conduct business.

High Efficiency Load Evaporator:

By applying gravity type refrigerant distribution system, reliable operation is provided, and evaporation efficiency is improved by optimizing arrangement of eliminator and evaporator tube.

Oil Recovery System:

The oil supplied during the high-speed rotation of the compressor is recovered through a three-stage separation system. When refrigerant is moved, it prevents impurities from entering and improves cooling efficiency. By continuously supplying and recovering oil, oil shortage can be prevented.

Reduced Weight & Size:

Valuable floor space can be saved by reducing installation area and weight.

Noise Reduction:

It minimized turbulence in intake port and reduced inconvenience of noise by preventing outflow.

Black Box Feature:

It stores and analyzes operation record for quick diagnosis to provide solution in case of failure.

Oil Free Centrifugal Chiller

LG's oil free chiller has simplified the piping structure by eliminating oil-related parts. There is no need to replace oil or filters. LG will revolutionize the way you conduct business.

Improved Partial Load Efficiency:

It is possible to precisely control up to 0.1Hz by adjusting the number of rotations through frequency control according to the load. Precision control improves the partial load efficiency by 54% compared to the Two-stage model running at a fixed speed, saving energy and cost.

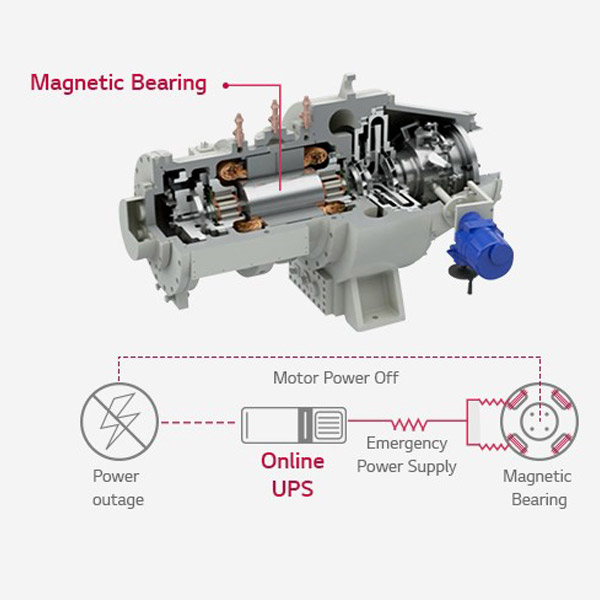

Magnetic Bearing:

The non-contacting Magnetic Bearing technology has improved lubrication loss and enhanced energy efficiency. Moreover, Online UPS is installed to provide emergency power during sudden blackouts in order to maintain the rotation of rotary shaft and protect bearing to operate stably.

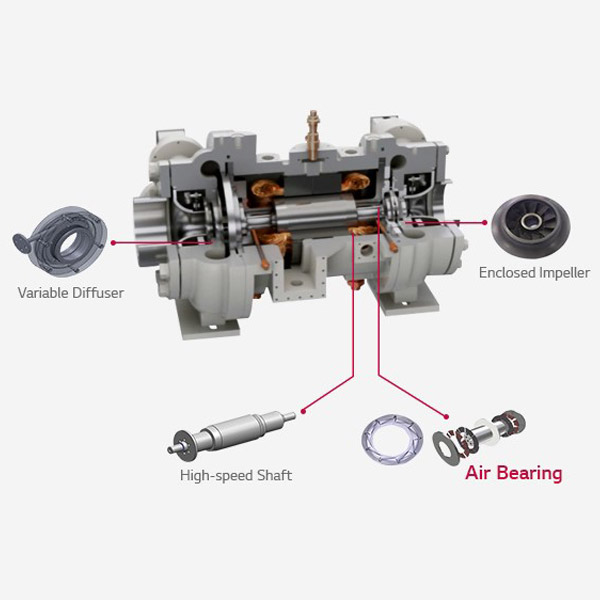

Air Bearing:

LG’s exclusive Air Bearing technology reduces friction loss and improves overall efficiency. Because it is technologically advanced, Air Bearing technology is applied in various industries such as industrial and aircraft applications.

Simplified Piping:

Oil-free chiller has simplified the piping structure by eliminating oil-related parts. There is no need to replace oil or filters, so users can save time and money at the same time.

Low-noise:

By simplifying the structure of compressor and eliminating the cause of the noise, it can be applied to areas requiring low vibration and low noise by reducing noise up to 74dB(A).

Compact Design:

The application of the non-lubrication system maximizes the space usage with compact product. It is an ideal solution that can be installed in the remodeling site where the place is narrow.

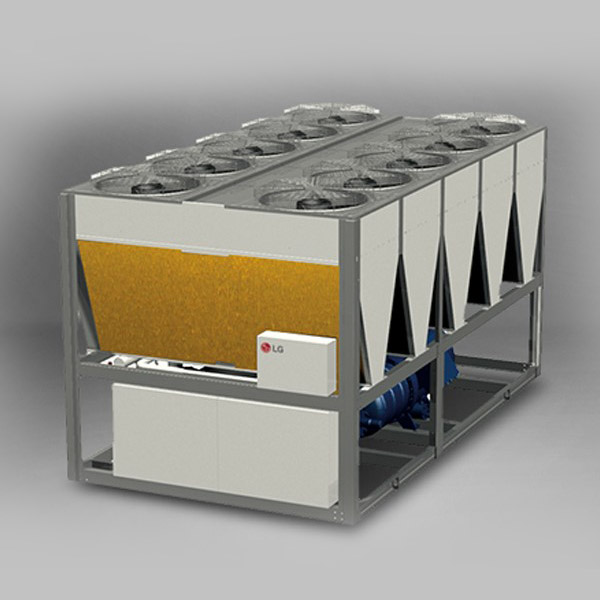

Air Cooled Screw Chiller

LG's Air-cooled Screw Chiller with its Ice Storage System cools the indoor area during the day and produces ice throughout the night. LG will revolutionize the way you conduct business.

Micro Channel Heat Exchanger (MCHX):

Made of 100% aluminum alloy material, Micro Channel Heat Exchanger(MCHX) has good heat transfer efficiency and is resistant to corrosion. The heat exchange area has increased compared to the conventional fin, and the weight and volume have been reduced, resulting in a compact product.

High Efficiency Condenser & Wide Louver Fin:

The V-shaped condenser structure has increased the heat transfer area as opposed to the conventional W-type model. The heat transfer efficiency is greatly improved in comparison to the conventional product by applying Wide Louver Fin.

Reduced Weight & Size:

Valuable floor space can be saved by reducing installation area and weight.

Noise Reduction:

It minimized turbulence in intake port and reduced inconvenience of noise by preventing outflow.

Black Box Feature:

It stores and analyzes operation record for quick diagnosis to provide solution in case of failure.

Absorption Chiller

Absorption Chiller Direct Fired Type:

Absorption Chiller uses chemical refrigerating cycle using Li-Br absorbent. It is eco-friendly by using water as a refrigerant and can utilize energy resources efficiently through various heat sources such as gas, hot water and steam.

Absorption Chiller Steam Fired Type:

Absorption Chiller Steam Type uses heat instead of electricity, which is highly recommended for areas with electricity shortage. It is a more environmentally friendly and economical product because it uses the heat energy source from the surrounding thermal power plant as a heat source.

Absorption Chiller Hot Water Type:

Absorption Chiller Hot Water Type uses heat instead of electricity, which is highly recommended for areas with electricity shortage. This type of model utilizes the waste water from nearby factories and power plants, and provide cooling/heating operation through these heating sources.

Absorption Chiller Complex Type:

Absorption Chiller Complex Type uses heat instead of electricity, which is highly recommended for areas with electricity shortage. It is an economical and efficient product because it can use multiple heating heat sources according to installation environment and need.

High Performance Stainless Steel Tube:

Specially manufactured stainless steel heat pipe with LG's exclusive technology has the same heat transfer performance as copper pipe and has very high corrosion resistance compared to copper pipes, ensuring stable heat transfer performance even for long time operation.

Absorbent Concentration Control & Prevention of Power Failure:

The absorption control concentration is calculated by the crystal control protection logic built in the controller, and the prevention control is executed when the concentration rises above the set value. By controlling the absorption liquid concentration automatically, it prevents the pre-absorption of liquid crystals and calculates the time from the power failure to the completion of power recovery through the independent timer built in the product.

Superior Installation Convenience:

3 Parts Partition enables easy installation at narrow places such as remodeling & renovation sites.

Easy Pipe Cleaning:

When cleaning the piping, only the water box cover can be opened without disconnecting the piping.

Digital Pressure Check:

Digital pressure gauge is used to monitor the pressure inside the refrigerator in real time. The vacuum rate is automatically set and saved. The saved data can be used to accurately and quickly monitor and diagnose leakage.

Chiller Plant Ancillary Equipments

REFRIGERANT RECOVERY UNIT

- Portable machine specifically designed to recover large volumes of refrigerant.

- Compatible with CFC/HCFC/HFC refrigerants

- In-built protection system

- Compact and portable

Ideal For:

- Transferring refrigerants on large job-sites

- Supermarkets

- Chiller plants

- Cold storage and production

REFRIGERANT STORAGE TANK

- ASME Refrigerant Tank

- Mounted on

- casters

- Relief Valve

- Pressure gauge

- Sight glass windows

- Float switch

- Bottom drain connection

- Liquid & Vapor ports

REFRIGERANT LEAK DETECTION SYSTEM

- Multi-gas Detection and Notification Refrigerant Leak Detection and Monitoring Systems

- Microprocessor based digital signal processing

- Continuous monitoring of all refrigerant gases

- Monitors single or multiple, local and remote locations

- Provides notification when gas concentration reaches preset alarm levels

- Alarm relays and analogue outputs are designed to activate remote devices or to interface with building automation (BAS)system